Zero Emissions

Over 60 years protecting your patients, instruments & environment

Andersen’s exclusive EO-Flexible Chamber Technology (EO-FCT) and abatement system work together to drastically limit EO consumption and emissions.

On this page:

How our Abators Work

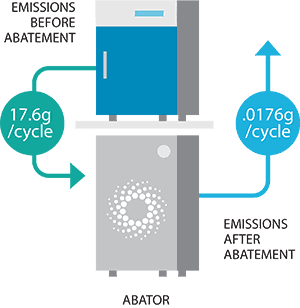

Andersen EO abators are a simple, cartridge-based system that employs a dry catalyst resin. Resin converts ethylene oxide to biodegradable organic compounds.

The abator removes 99.9% of EO in the exhaust stream, resulting in a fraction of a gram of total EO emissions throughout a multi-hour cycle. This tiny amount of EO is vented to the outside where it disperses rapidly, quickly becoming undetectable. Effectively making the process zero emission.

Each replaceable cartridge lasts 200 sterilization cycles. Spent cartridges are non-hazardous and may be discarded in most landfills or returned to Andersen for disposal.

Installation is simple. The abator attaches easily to all new Anprolene and EOGas 4 sterilizers. If you have an older model, call your account manager for guidance.

A similar abator is available for EOGas 3 sterilizers.

Anprolene Emissions by the Numbers

Single cycle emissions for an Anprolene sterilizer:

An Anprolene sterilizer releases 17.6 grams over its full sterilization/purge cycle.

WITH an ABATOR, an Anprolene system releases 0.018 grams/cycle. That’s less than 1/50 the weight of a regular paperclip.

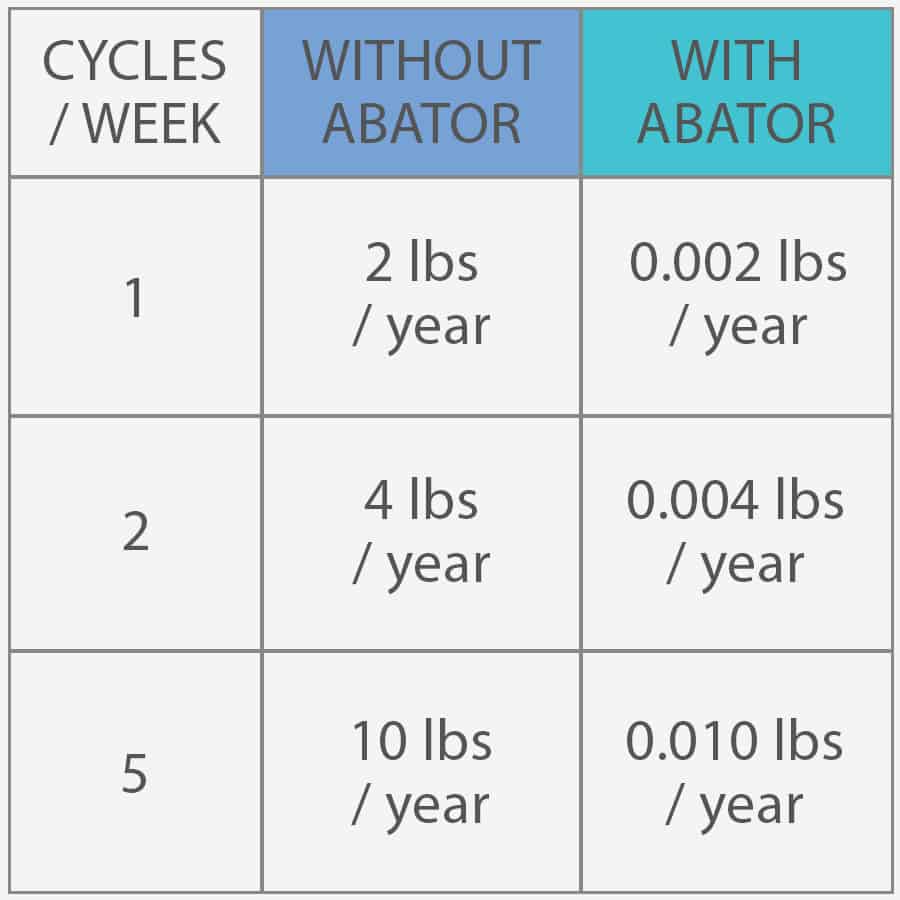

TYPICAL ANPROLENE EMISSIONS:

Maximum Potential Anprolene Emissions:

An Anprolene sterilizer that is operated for 24 hours a day, 365 days per year, still only emits a total of 24 lbs. of EO per year.

With an abator this maximum potential reaches 0.024 lbs. That’s less than the weight of two pop tabs.

To put these numbers in perspective, the US EPA does not require abatement of an EO emissions source until volume exceeds 2,000 lbs.

Check the Math

Emissions Data for Andersen Anprolene Sterilization System:

The Andersen Anprolene sterilizer uses a 17.6-gram, 100% ethylene oxide (EO) cartridge. The cycle time is 12 hours of sterilization with a 2-hour aeration cycle, for a total 14-hour minimum cycle (some loads may require additional aeration). The AN5100 Abator has a demonstrated efficiency of 99.9%.

| Annual Emissions based on typical usage: | Without Abator | With Abator 1 |

| Light use (one cycle per week): | 2 lb. / .92 kg | 0.002 lb. / 0.0009 kg |

| Medium use (two cycles per week): | 4 lb. / 1.83 kg | 0.004 lb. / 0.0018 kg |

| Heavy use (five cycles a week): | 10 lb. / 4.57 kg | 0.010 lb. / 0.005 kg |

| Annual Maximum Emissions: | 24.3 lb. / 11 kg | 0.024 lb. / 0.011 kg |

Annual Maximum Emissions calculations:2

- Hours in a year: 365 x 24 = 8,760

- Maximum potential number of Anprolene cycles in a year:3 8,760/14-hour cycle = 625.7

- Maximum potential grams used per year: 625.7 x 17.6 = 11,012

- Maximum potential emissions per year: 11,012/453.6 = 24.28 lbs. /11 kg

1: These tested efficiency numbers are based upon Andersen Sterilizers’ laboratory test – “Efficiency Testing for the AN5100 Cartridge Abator and the AN5200 Barrel Abator.”

2: The Annual Maximum Emissions calculation assumes that a sterilizer is run 24 hours a day, seven days a week, for all 365 days of a year. This calculation is used by some regulatory agencies to determine the maximum potential emissions from a system. It does not include additional aeration time and does not reflect the usage or the emissions of a typical user/facility.

3: Assumes no additional aeration. In practice, many loads will require 12 to 24 hours of additional aeration in the cabinet.

EOgas 4 Emissions by the Numbers

Single cycle emissions for an EOGas 4 sterilizer:

The EOGas 4 sterilizer releases 17.6 grams over its sterilization/purge cycle.

WITH an ABATOR, an Anprolene system releases 0.018 grams/cycle. That’s less than 1/50 the weight of a regular paperclip.

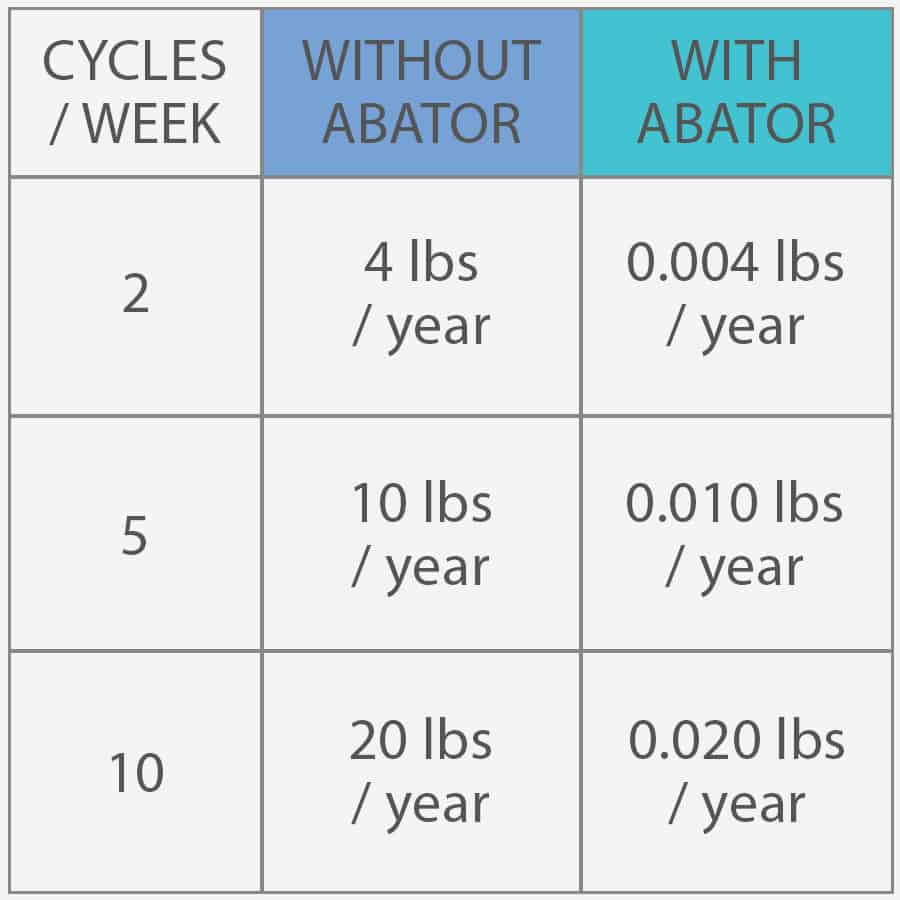

TYPICAL EOGAS 4 EMISSIONS:

Maximum Potential eogas 4 Emissions:

An EOGas 4 sterilizer that is operated for 24 hours a day, 365 days per year, still only emits a total of 97.1 lb. of EO per year.

With an abator this maximum potential reaches 0.097 lbs. That’s about the weight of 19 pennies.

To put these numbers in perspective, the US EPA does not require abatement of an EO emissions source until volume exceeds 2,000 lbs.

Check the Math

Emissions Data for Andersen EOGas 4 Sterilization System:

The Andersen EOGas 4 sterilizer uses a 17.6-gram, 100% ethylene oxide (EO or EtO) cartridge. The cycle time is 3 hours of sterilization with a 0.5-hour purge cycle, for a total 3.5-hour minimum cycle (some loads may require additional aeration). The AN5200 Abator has a demonstrated efficiency of 99.9%.

| Annual Emissions based on typical usage: | Without Abator | With Abator 1 |

| Light use (two cycles per week): | 4 lb. / 1.8 kg | 0.004 lbs. / 0.002 kg |

| Medium use (five cycles per week): | 10 lb. / 4.5 kg | 0.010 lbs. / 0.005 kg |

| Heavy use (ten cycles a week): | 20 lb. / 9.1 kg | 0.020 lbs. / 0.009 kg |

| Annual Maximum Emissions: | 97.1 lb. / 44 kg | 0.097 lbs. / 0.044 kg |

Annual Maximum Emissions calculations:2

- Hours in a year: 365 x 24 = 8,760

- Maximum potential number of Anprolene cycles in a year: 8,760 / 3.5-hour cycle = 2,502.93

- Maximum potential grams used per year: 2,502.9 x 17.6 = 44,050

- Maximum potential emissions per year: 44,050/453.6 = 97.1 lb. / 44 kg

1: These tested efficiency numbers are based upon Andersen Sterilizers’ laboratory test – “Efficiency Testing for the AN5100 Cartridge Abator and the AN5200 Barrel Abator.”

2: The Annual Maximum Emissions calculation assumes that a sterilizer is run 24 hours a day, seven days a week, for all 365 days of a year. This calculation is used by some regulatory agencies to determine the maximum potential emissions from a system. It does not include additional aeration time and does not reflect the usage or the emissions of a typical user/facility.

3: Assumes no additional aeration. In practice, many loads will require 12 to 24 hours of additional aeration in the cabinet.

EO Emissions in Perspective

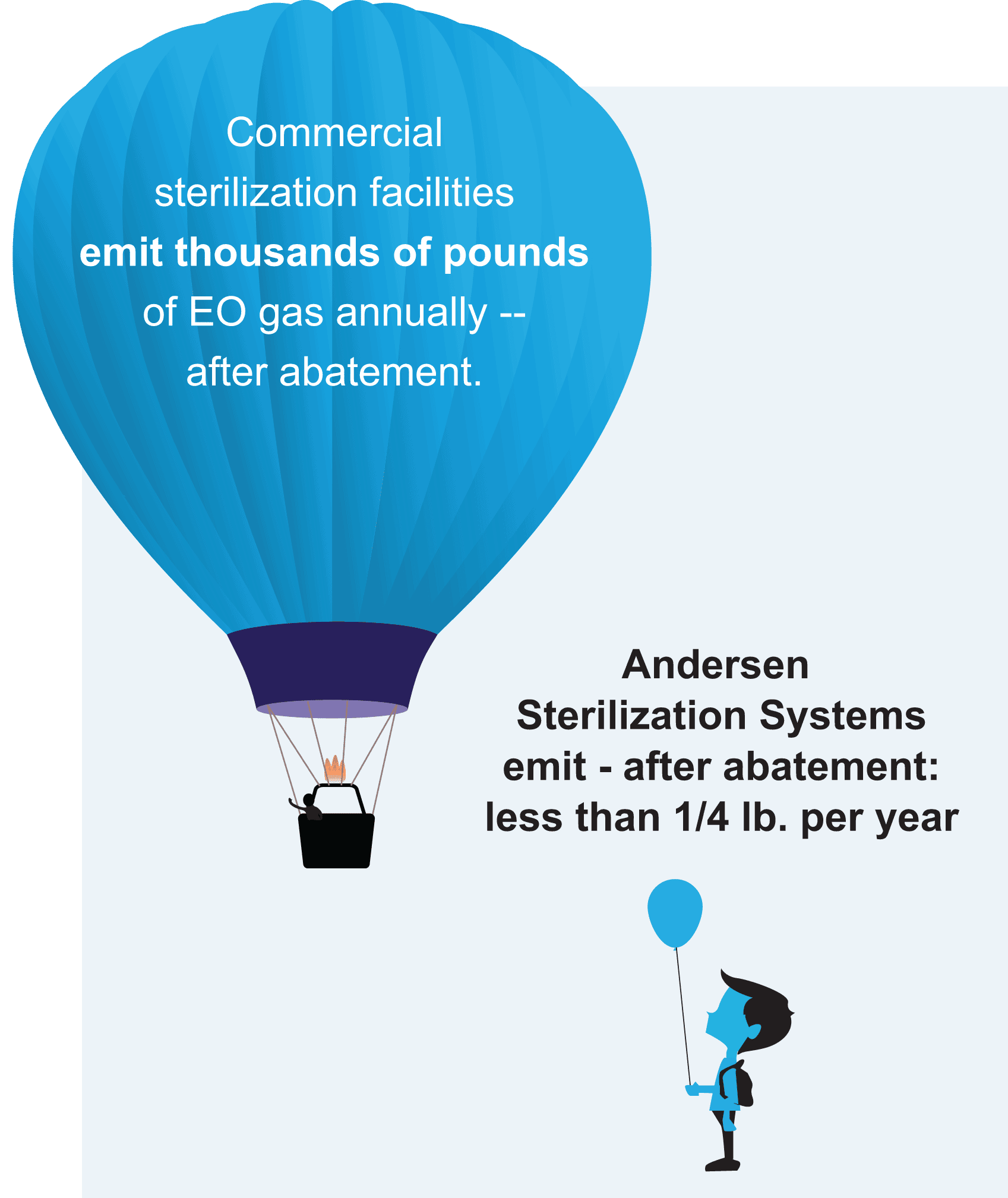

Several customers have contacted us regarding news articles reporting high emission levels from commercial EO sterilization plants. They ask how these systems compare to an Andersen sterilizer’s emissions.

The simple answer? There is no comparison.

Commercial EO sterilization facilities operate large pallet chambers that can release hundreds of thousands of pounds (in some instances, over three tons) of EO into the environment per year. In contrast, all Andersen sterilizers, when equipped with an abator, emit under a pound of EO per year.

Emissions Regulations in the United States

In the US, emission standards are managed nationally by the Environment Protection Agency (EPA). EPA does not require emissions abatement of ethylene oxide exhaust until volume exceeds 1 ton/year. For less than 1 lb. / year, the Andersen Sterilization Systems’ emissions meet (and exceed) all US national and state regulations.

In the United States, ethylene oxide (EO) emissions at the Federal level are governed by EPA Title V requirements, which state:

Sterilization sources using less than 1 ton (2,000 lbs. / 907 kg) are not subject to the emissions standards in §63.362 (i.e. there are no Federal requirements for emissions abatement at this level)