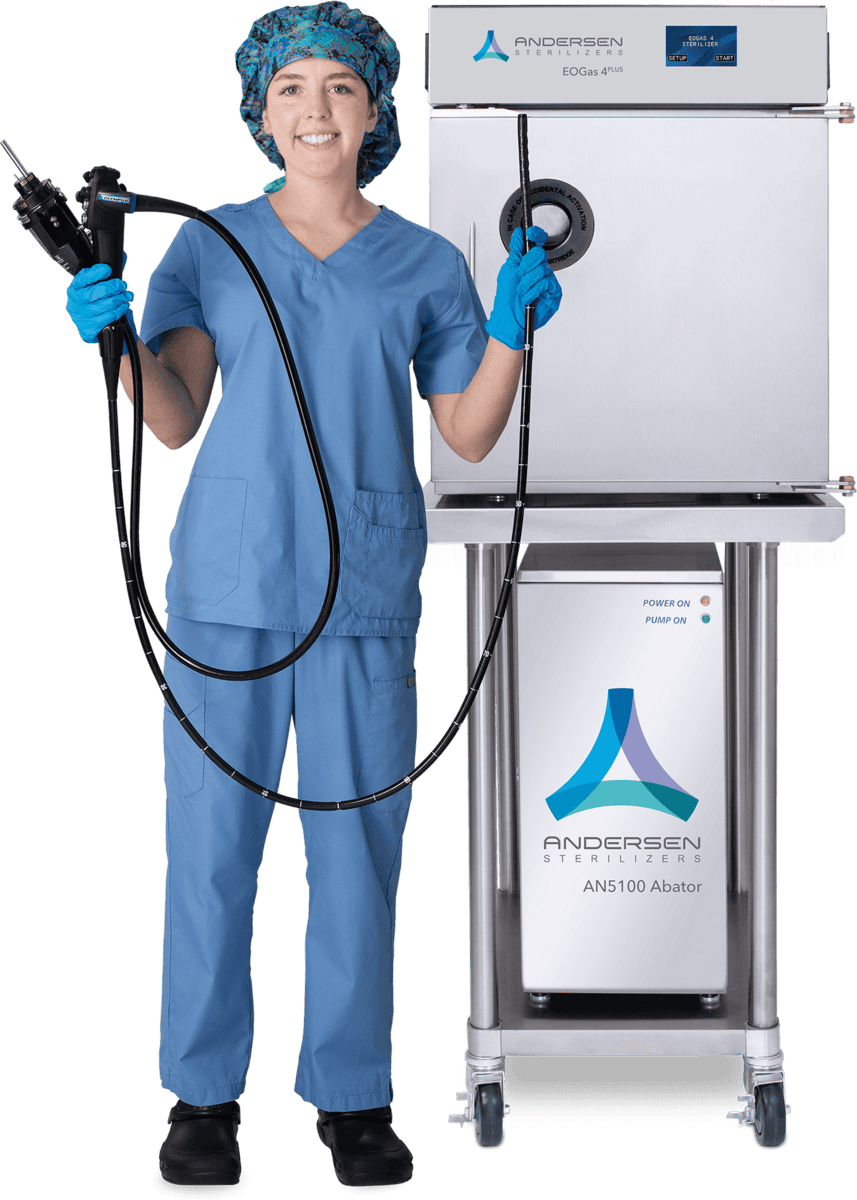

Replacing a soon-to-be-retired EO gas system?

Andersen Sterilizers® Solutions vs. 3M™ Solutions

When selecting a sterilization solution for medical devices, including long and complex medical devices, healthcare facilities should weigh factors such as FDA clearance, instrument compatibility, environmental impact, and workflow efficiency. This comparison highlights key features of the 3M™ Steri-Vac™ sterilizer, currently offered under the Solventum brand, and the Andersen EOGas 4,PLUS® the first FDA-cleared system specifically validated for long-lumen endoscopes. Understanding the strengths of each system helps organizations make informed decisions aligned with their infection prevention goals and operational needs.

| 3MTM (Solventum) Solutions | Andersen Sterilizers® Solutions | |

|---|---|---|

| Manufacturer | Solventum (formerly 3M Health Care) | Andersen Sterilizers |

| Technology | Ethylene Oxide (EO) with Negative Pressure System | Ethylene Oxide (EO) with Flexible Chamber Technology® |

| FDA 510(k) Clearance | Cleared for the sterilization of general medical devices | Cleared for the sterilization of general medical devices and the only FDA-cleared system for terminal sterilization of duodenoscopes and colonoscopes with more than 1100mm lumen lengths |

| Sterility Assurance Level (SAL) | 10-6 | 10-6 |

| Chamber Type | Rigid stainless steel chamber requiring a large dose of EO (100 – 170 grams) to achieve terminal sterilization | Ethylene Oxide-Flexible Chamber Technology®. Medical devices are loaded into a sterilization bag, which is then placed in a stainless steel cabinet. Before the sterilization cycle, the excess air is removed from the sterilization bag, thus requiring a microdose of gas (just 17.6 grams) to achieve terminal sterilization. |

| Endoscope Compatibility | General compatibility; not cleared for long lumen scopes like duodenoscopes | FDA-cleared to sterilize complex lumens (up to 1100mm), including duodenoscopes and colonoscopes ≤3530mm. |

| Cycle Times | Varies depending on load and EO concentration plus an additional 48 hours incubation period for 3M biological indicator. | 3- and 6-hour ethylene oxide exposure cycles plus an additional 4 to 48 hours biological indicator incubation period, depending on the BI used. Andersen offers several types. |

| EO Dose per Cycle | 100 to 170 grams of ethylene oxide per cycle stored in canisters | Ultra-low dose: only 17.6 grams of ethylene oxide per cycle (one and a half tablespoons), hermetically sealed ampoules within a rigid plastic cartridge. Does not leak or require special storage. |

| Environmental Impact | Requires dedicated catalytic EO abatement | EOGas 4 PLUS is eco-friendly and features low emissions. An optional abator reduces emissions further to 99.9%. Andersen’s abators employ a dry catalyst resin that converts ethylene oxide to biodegradable organic compounds. |

| Installation Requirements | Ventilation, plumbing, power (requires significant power compressors and waterlines) | Simple setup: 120-volt or 230-volt outlet and a one-inch exhaust (power requirements similar to a hairdryer) |

| Sterilization & Aeration | Often separate chambers | Sterilization and active aeration in one chamber |

| Controls & Interface | Advanced control systems with cycle customization | Simplified digital display |

| Safety Features | Sealed system, EO sensors, auto door lock | Auto door lock, controlled temperature environment, purge probe with built-in Process Challenge Device (PCD) |

| Device Size | Larger footprint (varies by model) | Compact tabletop unit: 29.5″ L x 22″ W x 28″ H |

| Maintenance | Requires regular calibration and EO monitoring | Annual maintenance suggested; 200-cycle abator cartridge, minimal user intervention |

| Training & Support | Varies | Free operator training for life of the system |

| Ideal For | High-throughput central sterile supply departments (CSSDs) | A complement to any infection control strategy that employs autoclave and H2O2 systems. Perfect for hospitals, endoscopy suites and specialty clinics seeking safe, low-emission EO sterilization for sensitive devices and long lumens. |

Recap: Key Points to Consider

- Andersen EOGas 4PLUS is the only FDA-cleared system for terminal sterilization of long-lumen duodenoscopes and colonoscopes.

- 3M™ Steri-Vac™ (Solventum) is a proven, large-scale EO system ideal for high-volume hospitals and CSSDs.

- EOGas 4PLUS uses a minimal EO dose (17.6 g) and offers ultra-low emissions with a simple abator system.

- EOGas 4PLUS enables sterilization and aeration in a single chamber, simplifying workflow and saving space.

- Both systems meet the highest sterility assurance level (10⁻⁶), but EOGas 4 PLUS offers unmatched compatibility for delicate and complex devices, is FDA-cleared, low voltage, low cost per cycle, and features EO-Flexible Chamber Technology,® allowing for the use of far less gas to achieve terminal sterilization.

Protect Your Patients.

Preserve Your Instruments.

EOGas 4PLUS is the only system in the world proven to sterilize the longest lumens. Andersen’s award-winning EO-Flexible Chamber Technology enables EOGas 4PLUS to achieve terminal sterilization using 10 times less gas (17.6 grams per cycle) than its competitors, whose systems feature a rigid chamber. When paired with an Andersen abator, this system has zero emissions.

CONCLUSION

The 3M™ Steri-Vac™ Sterilizer and Andersen EOGas 4PLUS® represent robust solutions for EO sterilization, but they are designed with different operational priorities in mind. Steri-VacTM is good for facilities with infrastructure in place for high-throughput, rigid chamber EO systems that want to maintain compatibility with a range of sterilization supplies and accessories.

EOGas 4PLUS can sterilize the same items as the Steri-vacTM, and it stands out for its FDA clearance to sterilize complex and ultra-long lumen devices, including duodenoscopes and colonoscopes. Its compact design, low EO usage, integrated aeration, and user-friendly interface make it an excellent fit for clinics, endoscopy centers, and hospitals that prioritize flexibility, safety, and simplicity in their infection prevention strategy. EOGas 4PLUS is a complement to other high-throughput technologies such as steam and H2O2. Modern SPDs should consider having at least two EOGas 4PLUS systems to complement their other sterilization systems.

Connect with Our Sterilization Experts

Ready to upgrade your sterilization process? Our experts are here to help you choose the right solution for your facility’s needs — whether you’re dealing with complex instruments, space constraints, or stricter safety standards. Contact us now for personalized guidance and a quick demo. Let’s improve your infection prevention strategy today.