High-Capacity Sterilization

EOGas 3

EOGas 3® sterilizers are designed for maximum efficiency and user-friendliness. With a microprocessor that manages bag tracking, operators can seamlessly load and unload while maintaining optimal sterilization processes.

Best for Manufacturing & Large Facilities

EOGas 3: High-Capacity Sterilization Made Simple

EOGas 3® sterilizers are designed for both efficiency and ease of use. A built-in microprocessor monitors the sterilization process, allowing operators to load new bags or unload finished bags without interrupting ongoing cycles. With three operating modes, 10⁻⁶ SAL terminal sterilization, and integrated aeration within the cabinet, the system offers the flexibility needed for efficient turnaround for high-volume workflows.

|  |  |

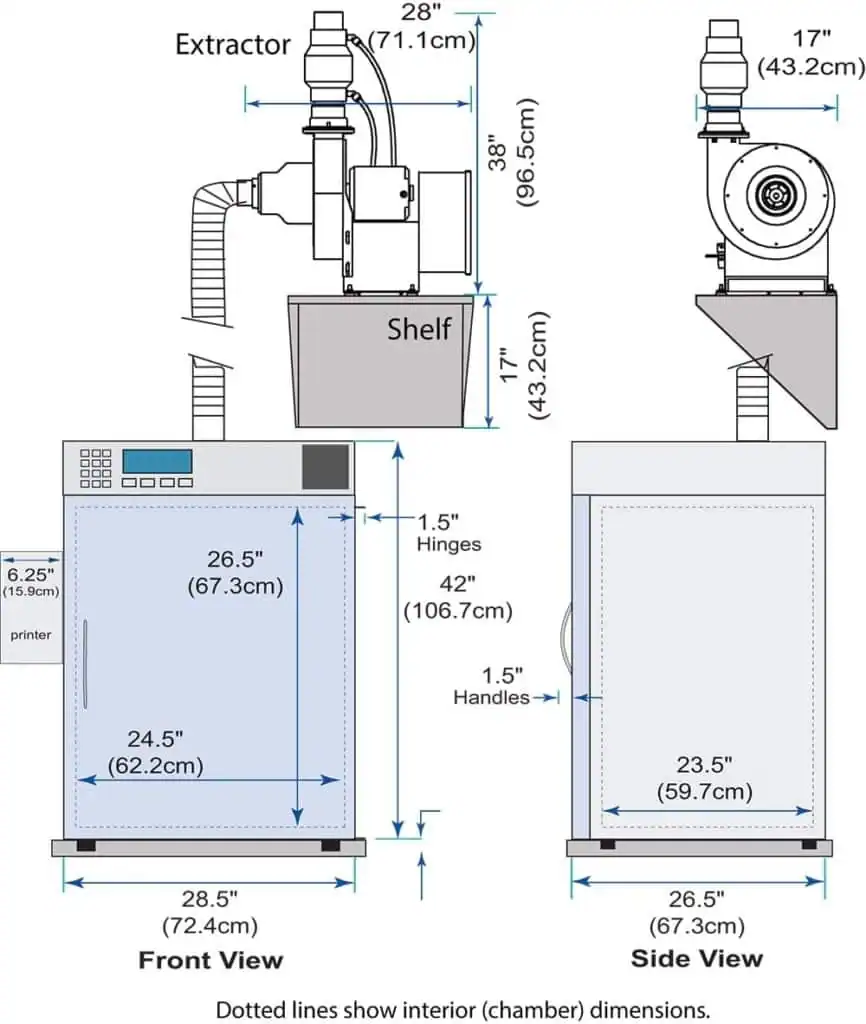

| Model | EOGas 310 | EOGas 333 |

| Description | Tabletop sterilizer cabinet, extractor and heat sealer | Freestanding sterilizer cabinet, extractor and heat sealer |

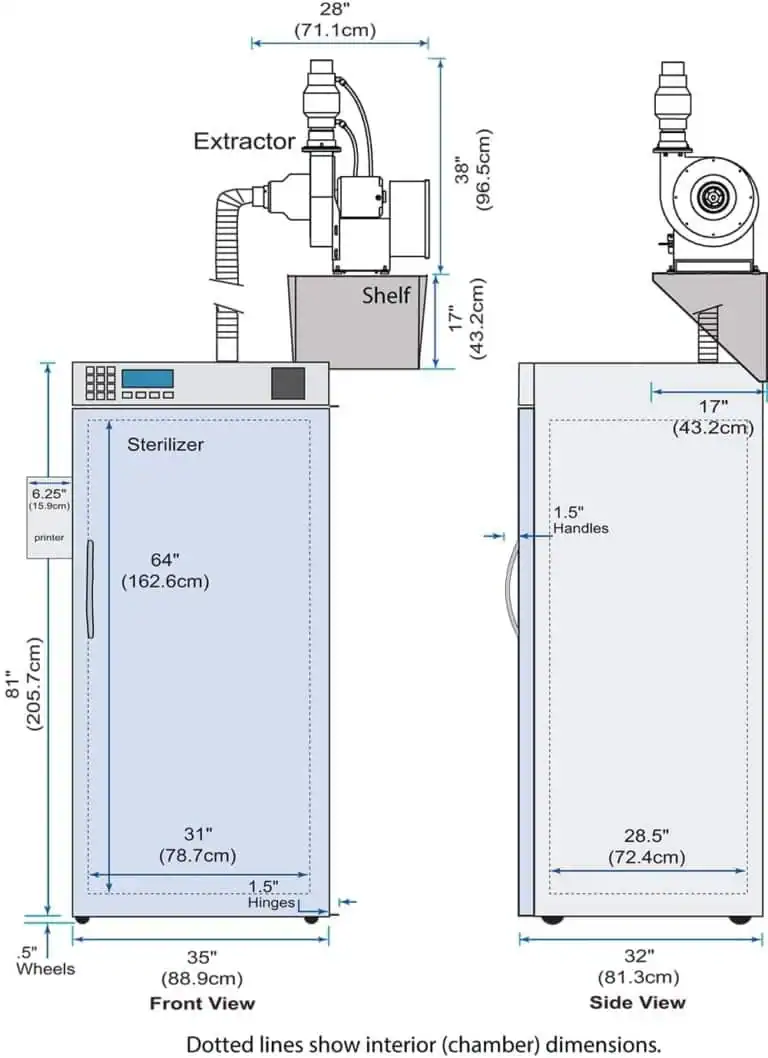

| Interior | 23.5″ L x 24.5″ W x 26.5″ H | 28.5″ L x 31″ W x 64″ H |

| Capacity | 10 cu ft (130 L) | 33 cu ft (930 L) |

| Cabinet Weight | 285 lbs (130 kg) | 630 lbs (286 kg) |

| Exhaust Requirements | Dedicated 3″ (7.6 cm) discharge vent | Dedicated 3″ (7.6 cm) discharge vent |

| Power Requirements | 220 – 240V +/- 10%, 5.4 Amps | 220 – 240V +/- 10%, 5.4 Amps |

| Validatable | ● | ● |

Image Gallery

Explore the EOGas 3 in Action

Accessories

Accessories Designed to Work Seamlessly with EOGas 3

Documents

User Manuals, Guides and Technical Documents for EOGas 3

Ethylene Oxide Safety Data Sheet – EO SDS

EOGas 3 Zero Emissions Math

English

Compare All Andersen Sterilizer Models

English

Health Canada License EOGas 3 & AN1006

English

EOGas 310 & EOGas 333 Specs

English

Instructions for Use EOGas 3

English French Spanish

Instructions for Use EOGas Cartridges

English French Spanish

Instructions for Use EOGas Cartridges

English French Spanish

Product Lifecycle Policy

English French Spanish

Instructions for Use EOGas 3 Gas Kit

English French Spanish

EOGas 310 SPECS

EOGas 333 SPECS

Best for Healthcare & Veterinary

Free Operator Training

Andersen provides free operator training for the lifetime of its sterilizers.

Videos

Coming soon.

Easy Interface

Easy to use interface and digital display. Sterilization status and cabinet temperature shown throughout the cycle

Revolutionary EO Cartridge

The 10.5g EO cartridge delivers terminal sterility using 90% less EO than any other system on the market.

Unmatched compatibility

While autoclaves and other modalities are ideal for fast, high-temperature sterilization, the EOGas 3 takes care of the rest — expanding your clinic’s capabilities.

Smart Cabinet Design

Operator safety is our first priority, this is reflected in the design and operation of EOGas 3 systems. The combination of the sealed sterilization cabinet and variable speed exhaust extractor give users confidence they can hear each time they open the door.

Efficient 16-Hour Cycle

Designed to achieve FDA-required 10-6 sterility assurance level for terminal sterilization of most medical devices. Includes integrated aeration, with both sterilization and aeration performed in a single cabinet.

35L Sterilization Bag

Make the most of every cycle with extra-large sterilization bags. The only multi-load sterilizer that allows users to add new loads while others are processing.

Make your System Zero Emissions

The Andersen AN5200 abator is a simple, drum-based system designed to remove more than 99% of the EO from the exhaust stream of an EOGas 3 sterilizer. The replaceable drum employs a dry catalyst resin that converts ethylene oxide to biodegradable organic compounds. The replaceable abator drum has a 1,800-cycle capacity. Spent drums are non-hazardous.

Learn more

Why Ethylene Oxide?

There are many benefits to ethylene oxide sterilization, some of which may be crucial to your hospital or clinic, especially when reprocessing complex multi-channel endoscopes and delicate medical devices. Andersen’s FDA-cleared sterilizers offer several advantages, including low per-cycle cost, low-temperature operation and EO-Flexible Chamber Technology, which allows our systems to use a microdose of EO — just 17.6 grams per cycle. Our systems are able to achieve terminal sterilization (10-6 SAL) with 90% less EO than our competitors — this is ethylene oxide sterilization reimagined.

Customer Testimonials

Our experience with Andersen has been outstanding.

Expert Guidance for Your Needs

Tell us about your sterilization requirements — our experts are here to guide you to the perfect EO solution.