When you manage the terminal sterilization of high-value, heat-sensitive medical devices, you cannot compromise on material integrity or a 10⁻⁶ Sterility Assurance Level (SAL). Traditional methods like steam or radiation often fail to protect delicate polymers and complex electronics, making the diverse applications of ethylene oxide sterilization indispensable to modern healthcare. By utilizing EO gas, you ensure deep penetration into multi-layered packaging and intricate lumens without the oxidative damage associated with other modalities.

This process currently safeguards approximately50% of all sterile medical devices in the U.S., ranging from drug-coated stents to sophisticated surgical kits. Your facility requires a balance between rigorous efficacy and operational safety, which is where proprietary EO-Flexible Chamber Technology redefines the standard. This innovative approach maximizes gas efficiency and ensures low emissions, providing a cost-effective solution that maintains FDA clearance and scientific reliability.

Key Takeaways

Ethylene oxide (EO) sterilization is the essential solution for high-value, heat-sensitive medical devices, protecting delicate polymers and electronics from the damage caused by steam or radiation.

EO-Flexible Chamber Technology achieves a 10⁻⁶ Sterility Assurance Level using a fraction of the gas required by traditional methods, significantly reducing environmental emissions and operational costs.

The high permeability of EO gas allows it to penetrate multi-layered packaging and intricate lumens, making it ideal for sterilizing complex instruments like drug-eluting stents and pre-assembled surgical kits.

Adopting localized gas diffusion technology enhances facility safety by minimizing chemical exposure while maintaining full regulatory compliance and scientific reliability.

Advanced Applications of Ethylene Oxide Sterilization

Sterilizing Heat-Sensitive Polymers and Multi-Layered Surgical Kits

When you manage high-value medical devices made from heat-sensitive polymers, you require a terminal sterilization process that preserves material integrity without sacrificing efficacy. Ethylene oxide provides a specialized solution for delicate instruments like catheters, ventilators, and heart valves that would otherwise degrade under the intense pressure and moisture of steam autoclaves.

Common heat-sensitive materials sterilized with EO include:

Plastics—Polypropylene, polyethylene, polycarbonate, and PVC are used in medical devices and packaging

Rubber and Elastomers – Silicone, latex, and flexible materials for medical gloves, catheters, seals, and gaskets

Textiles—Surgical drapes, gowns, and masks made from synthetic fibers

Multi-material surgical kits – Pre-assembled procedure packs containing multiple device types

By utilizing EO-Flexible Chamber Technology, you achieve a rigorous 10⁻⁶ Sterility Assurance Level while significantly reducing gas consumption and environmental emissions. The low-temperature nature of the cycle prevents warping or embrittlement, maintaining the precise tolerances required for modern surgical interventions.

The high permeability of EO gas allows it to migrate through breathable packaging materials and reach the internal lumens of intricate devices. This capability is essential for sterilizing pre-assembled kits containing surgical drapes, gowns, and single-use syringes, all in one cycle, eliminating the need for individual component processing.

Protecting Advanced Electronics and Drug-Coated Combination Devices

Modern medical innovation frequently relies on the integration of sensitive electronics and bioactive coatings that cannot withstand the aggressive thermal energy of steam or the ionizing radiation of gamma rays. When you manage the terminal sterilization of advanced pacemakers or drug-eluting stents, you require a process that achieves a 10⁻⁶ Sterility Assurance Level without compromising delicate circuit boards or volatile pharmaceutical layers.

Critical electronic and drug-coated devices requiring EO sterilization:

Pacemakers and implantable cardiac devices—Contain sensitive circuitry vulnerable to heat damage

Drug-eluting stents – Feature therapeutic coatings that degrade under high temperatures

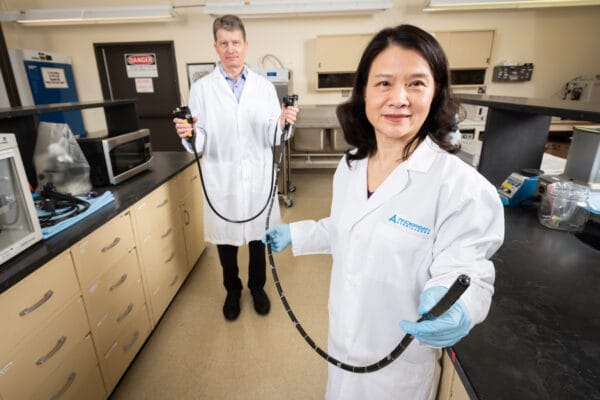

Electronic endoscopes and diagnostic tools – Combine optical, electronic, and mechanical components

Implantable drug delivery systems – Integrate pharmaceuticals with mechanical devices

Your facility can gain a competitive advantage by adopting EO-Flexible Chamber Technology, which optimizes gas consumption and enhances safety for both operators and the environment. This proprietary approach allows for high-efficacy sterilization using a fraction of the gas required by traditional industrial sterilizers, significantly reducing emissions while maintaining regulatory reliability. Because the process operates at exceptionally low temperatures, you can confidently process drug-coated combination devices without risking the degradation of therapeutic agents.

Sterilizing Complex Geometries and Intricate Lumens

Surgical instruments, including scalpel blades, forceps, and scissors, are sterilized with EO to maintain cleanliness and reduce the risk of infection. Items such as artificial joints, stents, and dental implants require sterilization without compromising their material properties, ensuring they remain free of contaminants and safe for insertion into the human body.

Flexible and delicate items like catheters and tubing benefit from EO’s ability to sterilize without deformation or damage. Urinary catheters and intravenous tubing need to be sterile to prevent infections, and EO provides a reliable sterilization option for these critical products.

Endoscopes, sensors, and other devices used in diagnostic procedures must be sterile to ensure patient safety. Andersen’s EOGas 4 is the only system in the world cleared by the FDA to sterilizeendoscopes with a working lumen length of >1100 mm.

EOGas 4, featuring award-winning EO-Flexible Chamber Technology, is the first sterilization system to receive FDA 510(k) clearance for terminal sterilization of duodenoscopes and colonoscopes. When you add EOGas 4 to your infection prevention line of defense, you protect your critically ill patients, preserve your fragile instruments, and safeguard your healthcare facility. Learn more abouthow Andersen’s sterilization process works to understand the complete cycle from loading to aeration.

Disposable items like syringes, bandages, gloves, and IV sets are commonly sterilized using EO gas, ensuring they remain free from bacteria, viruses, and other harmful microorganisms. Ethylene oxide sterilization is particularly valuable for items that have intricate designs or are made from a combination of materials, as it ensures thorough sterilization without requiring disassembly.

Enhancing Safety With EO-Flexible Chamber Technology

When you implement EO-Flexible Chamber Technology, you leverage a sophisticated localized gas diffusion method that redefines terminal sterilization for sensitive medical equipment. This proprietary approach allows you to achieve a rigorous 10⁻⁶ Sterility Assurance Level while utilizing a fraction of the gas required by traditional large-scale sterilizers.

Key advantages of EO-Flexible Chamber Technology:

Optimized gas efficiency—Uses a fraction of the gas compared to traditional industrial sterilizers

Reduced environmental emissions—Substantial reduction in EO released during aeration

Lower operational costs—Eliminates excessive infrastructure costs of industrial-sized abatement systems

Enhanced facility safety—Minimizes technician exposure through localized containment

Regulatory compliance—Meets stringent standards for high-volume throughput

By concentrating the EO gas within a specialized liner bag, the system ensures deep penetration into complex geometries, such as narrow-lumen catheters and multi-layered surgical kits. You can confidently process heat-sensitive polymers and delicate electronics without the risk of material degradation common with steam or radiation.

The versatility of this technology makes it an indispensable asset for sterilizing diverse inventories ranging from heart valves to veterinary surgical tools. You are no longer tethered to the logistical delays and high costs of off-site contract sterilization services. Instead, you can manage the sterilization of moisture-sensitive combination drug devices and complex procedure kits in-house with total control over the cycle parameters.

Material Compatibility and Technical Considerations

Several factors determine whether an item can be effectively sterilized with EO and how the applications of ethylene oxide sterilization are optimized for your specific inventory.

Critical compatibility factors to evaluate:

Material Composition – Verify compatibility before sterilization, as certain foams, natural rubbers, and biodegradable polymers may absorb EO gas or degrade under exposure.

Item Size and Shape – EO penetrates deeply into complex geometries and hard-to-reach areas, ensuring uniform exposure

Residual Gas Tolerance – Items require thorough aeration to remove traces before use, especially for medical implants

Regulatory Standards – Items must meet FDA and ISO standards for safe and effective EO sterilization.

Packaging Requirements – Special sterilization pouches or wraps ensure effective gas penetration while maintaining post-sterilization sterility.

Understanding how Andersen’s sterilization process works, including the aeration phase, ensures you can safely process even the most sensitive materials.

Ensuring Patient Safety Through Specialized EO Sterilization

In modern healthcare, EO gas sterilization remains an indispensable pillar of the global medical supply chain. Achieving a 10⁻⁶ Sterility Assurance Level is not merely a regulatory requirement but a critical commitment to patient safety across millions of procedures. While other modalities may compromise the structural integrity of advanced polymers or delicate electronics, EO provides a gentle yet formidable solution for terminal sterilization.

The integration of proprietary EO-Flexible Chamber Technology represents a significant evolution in how you manage sensitive inventory and operational overhead. This advanced approach optimizes gas consumption and significantly reduces emissions, providing a sustainable path forward that aligns with stringent environmental standards.

Our Service/Support team is dedicated to providing the technical expertise and routine maintenance required to keep your EO systems performing at peak efficiency.Discover how our team can transform your approach to the applications of ethylene oxide sterilization.

Frequently Asked Questions

Why is EO preferred over steam or radiation for high-value medical devices?

EO sterilization protects delicate polymers and complex electronics from the oxidative damage and thermal stress inherent in traditional methods. You ensure deep penetration into intricate lumens and multi-layered packaging while maintaining a 10⁻⁶ Sterility Assurance Level without compromising material integrity.

How does EO-Flexible Chamber Technology improve sterilization efficiency?

This proprietary technology localizes the sterilant within a flexible environment to maximize gas efficiency and minimize chemical consumption. You achieve superior results through this concentrated approach, which significantly reduces emissions and enhances overall cost-effectiveness for your facility.

What types of medical instruments are best suited for EO sterilization?

You should utilize EO for heat-sensitive and moisture-sensitive devices such as drug-coated stents, pacemakers, ventilators, and heart valves. This process is the industry standard for approximately 50 percent of all sterile medical devices in the U.S. because it preserves the functional precision of sophisticated surgical kits.

Can EO penetrate complex packaging?

Yes, the high diffusivity of EO gas allows it to permeate complex, multi-layered packaging that other modalities cannot reach. You can confidently process entire surgical kits, ensuring every component remains patient-ready and functionally pristine.

How does the EO process address environmental and safety concerns?

By implementing EO-Flexible Chamber Technology, you minimize chemical exposure and environmental impact through low-emission cycles. This method provides you with a safe, regulatory-compliant solution that balances rigorous efficacy with operational safety requirements.

What level of sterility assurance can I expect from this technology?

You achieve a terminal sterilization standard of 10⁻⁶ SAL, representing a one-in-a-million chance of a non-sterile unit. This rigorous benchmark ensures that even your most complex instruments meet the highest scientific standards for clinical reliability and patient safety.

Spread the Word

Expert Guidance for Your Needs

Tell us about your sterilization requirements — our experts are here to guide you to the perfect EO solution.