Comparing EO to Other Modalities

An Andersen ethylene oxide (EO) sterilizer is the perfect addition to any infection control strategy. It safely sterilizes delicate medical instruments without degradation. While autoclaves and other modalities are ideal for fast, high-temperature sterilization, Andersen sterilizers takes care of the rest — expanding your clinic’s capabilities.

Andersen EO sterilization provides low-temperature operation, poses minimal risk to operating personnel and is gentle on instruments. Its proven technology is compatible with almost all materials — including instruments made of plastic, those with electronic components and long lumens. By incorporating an EO sterilizer into your clinic’s infection control strategy, you protect your patients and preserve your instruments.

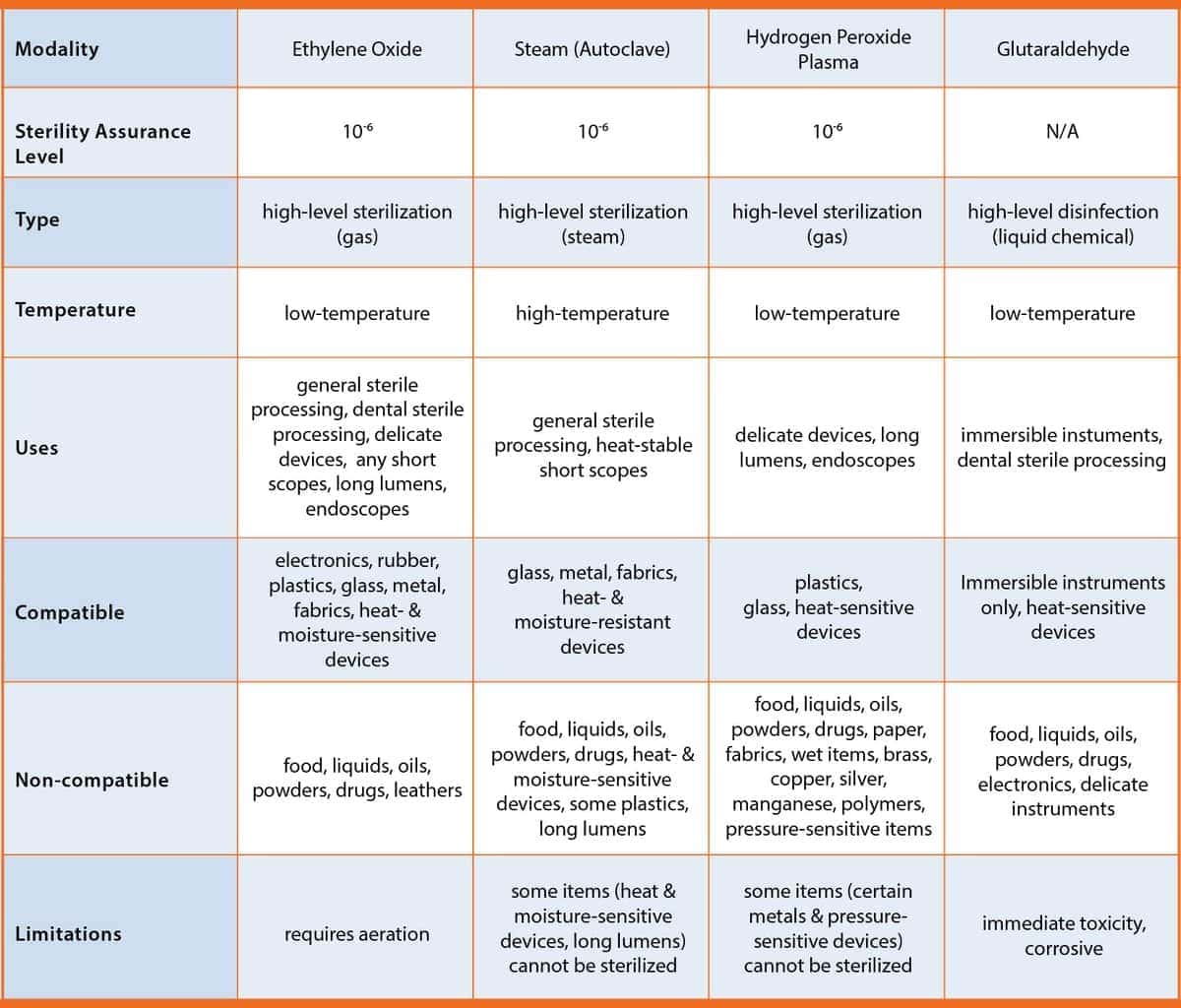

At-A-Glance

Ethylene oxide offers unique advantages in versatility and compatibility, especially for heat- and moisture-sensitive medical instruments. Ethylene oxide achieves a Sterility Assurance Level (SAL) of ≤ 10⁻⁶ at low temperatures. While methods like steam sterilization and hydrogen peroxide plasma are also highly effective and well-suited for many applications, they may have limitations with certain materials or device designs. Ethylene oxide complements these modalities by providing a proven sterilization option for instruments that may not be compatible with other systems, helping you to protect your most vulnerable patients.

Expert Guidance for Your Needs

Tell us about your sterilization requirements — our experts are here to guide you to the perfect EO solution.